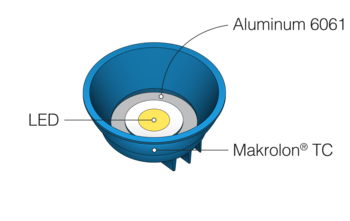

Heatsink Screener

using Makrolon® TC polycarbonate

provided by Covestro LLC

Additional Information

Simulation Information

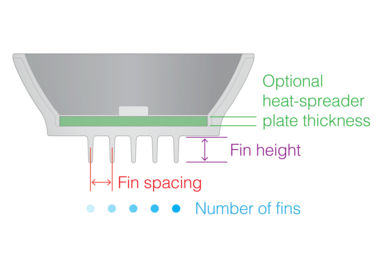

Design Space

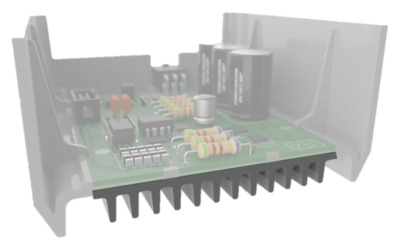

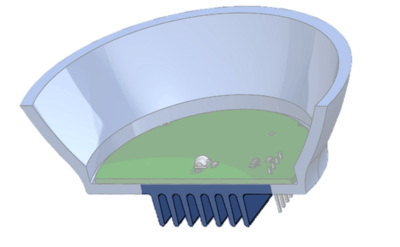

This Heatsink Screener uses two simulation models to predict LED temperatures:- The Makrolon® TC polycarbonate heatsink model uses a dataset based on the Design Space indicated below.

- The die-cast aluminum heatsink model uses the same Design Space, but without the aluminum heat-spreader plate.

Input Parameters

Thermal conductivity:

0.5 to 22.5 W/mK

Input power level:

5 to 18 Watts

Number of fins:

3 to 7 fins

Fin height:

5 to 30 mm

Fin spacing:

2.3 to 12.8 mm

Optional heat-spreader thickness:

0 to 3.3 mm

Ambient air temperature:

0 to 90 °C

Heatsink diameter:

63.5 mm (fixed)

Heatsink nominal wall thickness:

3.2 mm (fixed)

Screen Makrolon® TC Polycarbonate

By clicking "Screen Makrolon® TC Polycarbonate", you

agree to our Terms of Use and Privacy Policy.

agree to our Terms of Use and Privacy Policy.

Correlation

Experimental Correlation

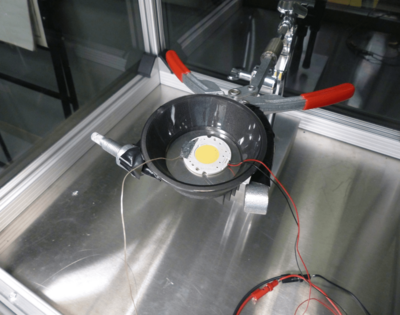

Heatsink Testing Setup

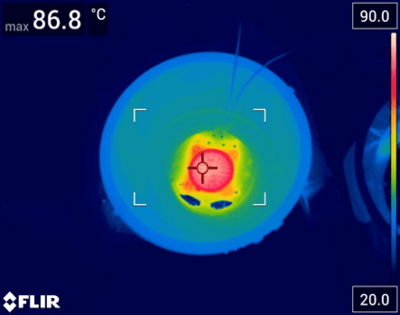

Thermal Image

- The LED temperature predictions of the Neural Network Model were compared to CFD simulations and experimental test data and were found to correlate well

(see next tab). - Maximum experimental LED temperatures were recorded with thermocouples and validated with thermal imaging.

- Thermal Conductivity values used to predict LED temperatures were calculated using the in-plane thermal conductivity ASTM measurement method, then increasing the result by 25%.

- Max Material Temperature used to generate warnings and cut-offs are calculated as 18 °C below the material’s Vicat softening temperature.